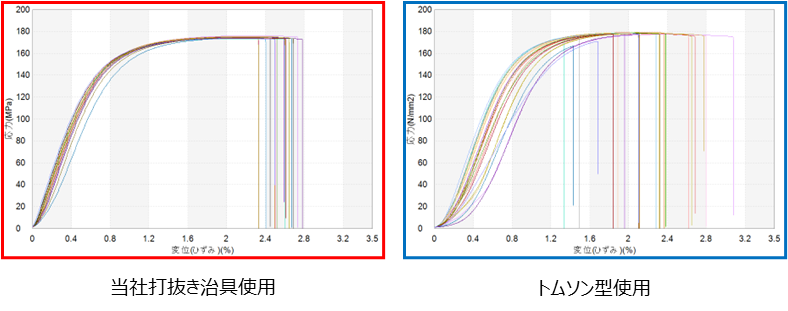

Results of a punching processability test of a lithium-ion battery electrode (Anode, 150 μm, double-side coated)

Lithium-ion batteries are a type of secondary battery designed for repeated charging and discharging cycles. They generate electrical energy through the movement of lithium ions between the cathode and anode. These batteries are widely integrated into electronic devices such as smartphones and laptops, and as a power source for electric vehicles. Despite their extensive adoption, the technology continues to evolve in fierce development competition worldwide, with ongoing efforts focused on improving energy efficiency, extending lifespan, and enhancing overall performance.

If the cathode and anode of a lithium-ion battery come into direct contact, a short circuit can occur. Burrs or sagging on the processed surface may penetrate the separator and touch the opposite electrode. Therefore, strict quality control during electrode processing is essential.

In this test, we used a specimen with a total thickness of 150 μm, consisting of a 8 μm copper substrate with active materials coated on both sides, and conducted a punching test using our precision punching tool with a clearance of 2 μm.

Test Conditions:

Test Specimen

Material: Anode substrate + Copper foil

Thickness: 150 μm(Copper foil 8 μm)

Test Equipment

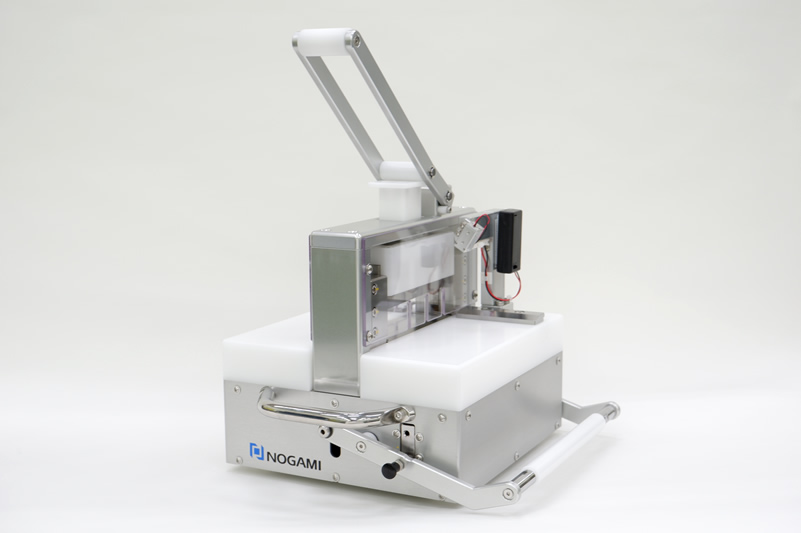

Punching jig: Nogamigiken’s Handheld Electrode Punch

Diameter: 10.00 mm

Clearance between the punch and the die: 2 μm

Microscope: KEYENCE VHX-6000

Magnification: up to 2500×

Test Results:

Top View of the Punched Anode

No burr or deformation is observed.

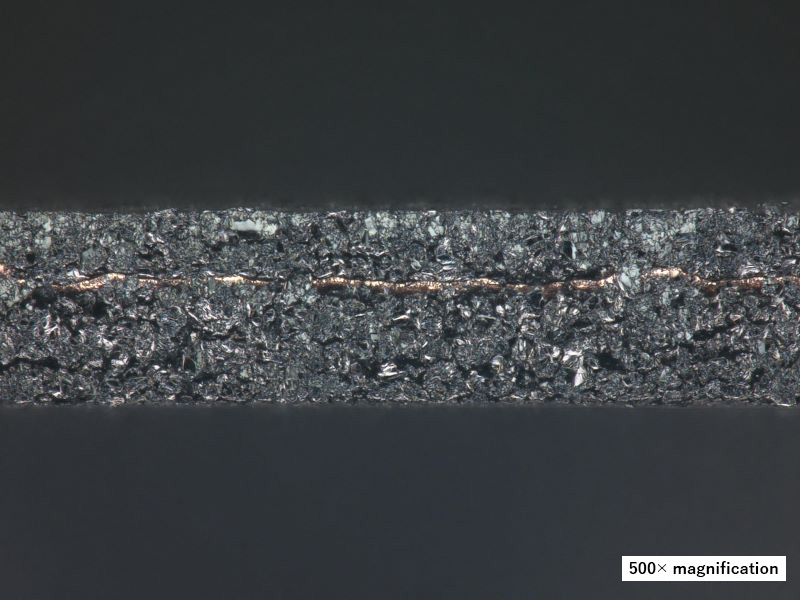

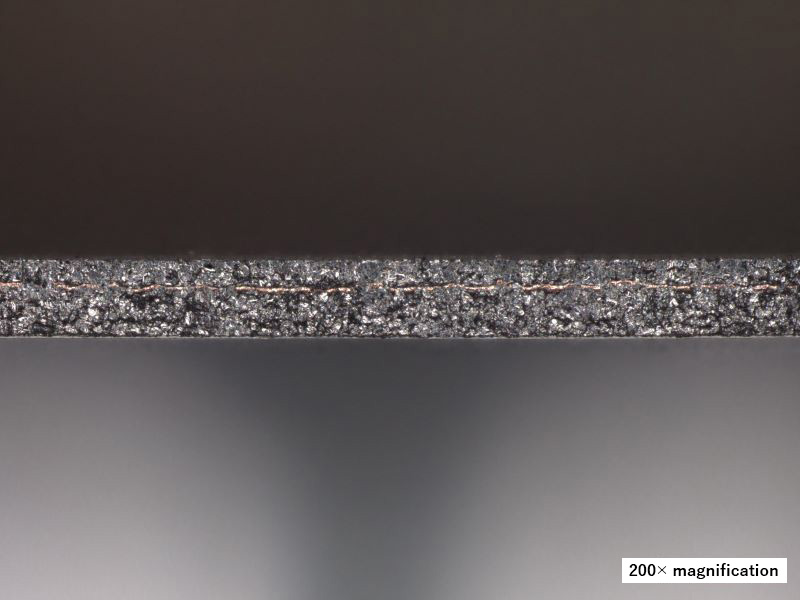

Cross section of the Punched Anode

The copper substrate layer also shows no burr or sagging, and the active material areas exhibit no irregularities.