company

About Us

Message from Top Management

Corporate Mission

“We are devoted to doing our business of MONODZUKURI (an art of making goods) with a great determination and good faith, creating valuable products and services, and making a contribution to society.”

Even since the company’s founding in 1970, we have intently devoted ourselves to the technology of grinding, and have responded to customer needs in a wide range of field. However, the speed of the technological innovation has continued to accelerate. Even in the machining industry, it is requested that we make a proposal which reads a few steps ahead of needs, and this proposal will be the best possible solution to customer’s problem. Under this sort of business environment, we laid down the corporate mission;

“We are devoted to doing our business of MONODZUKURI (an art of making goods) with a great determination and good faith, creating valuable products and services, and making a contribution to society”

Placing precision grinding technology as our core business basis, we continuously step up the reinforcement and efficiency of sections such as the research, design, production, assembly and service, and we will develop our unique technology integrating precision grinding and other techniques that we are only one to do.

We will keep on evolving in order to be a company that can create value of customers. We are looking forward to working with you on a long and lasting business relationship.

President and CEO Ryota Nogami

Our Products

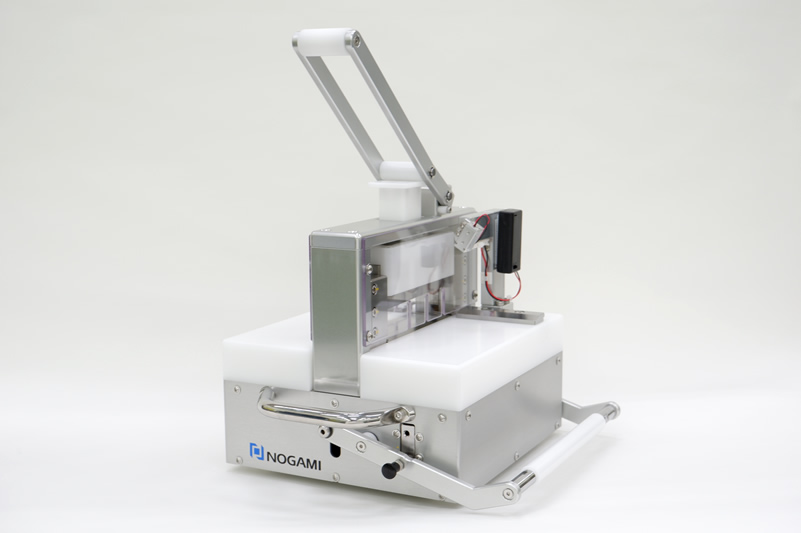

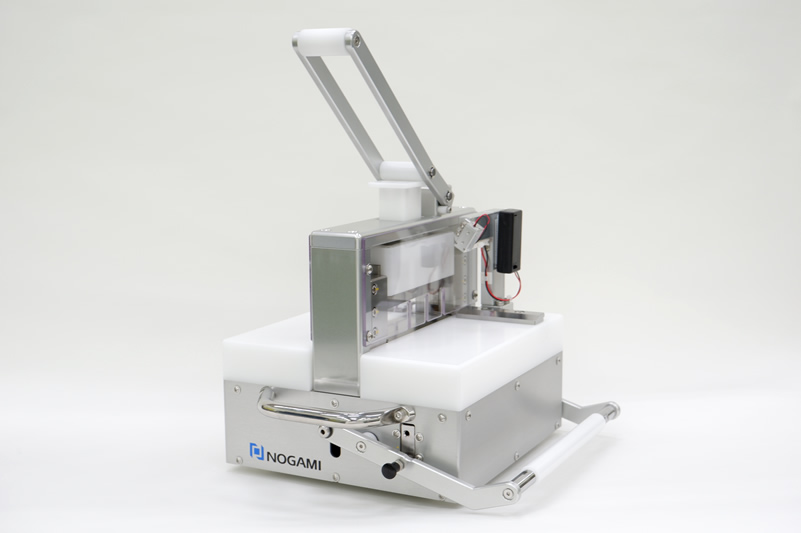

Handheld Electrode Punch

(φ1~26 mm/□1~22 mm)

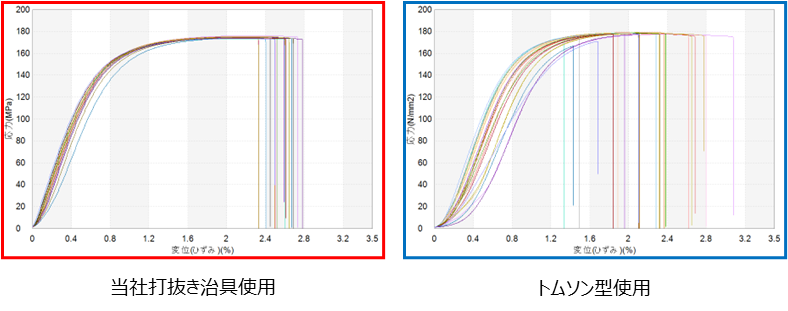

Punching jig for cross-sectional observation samples

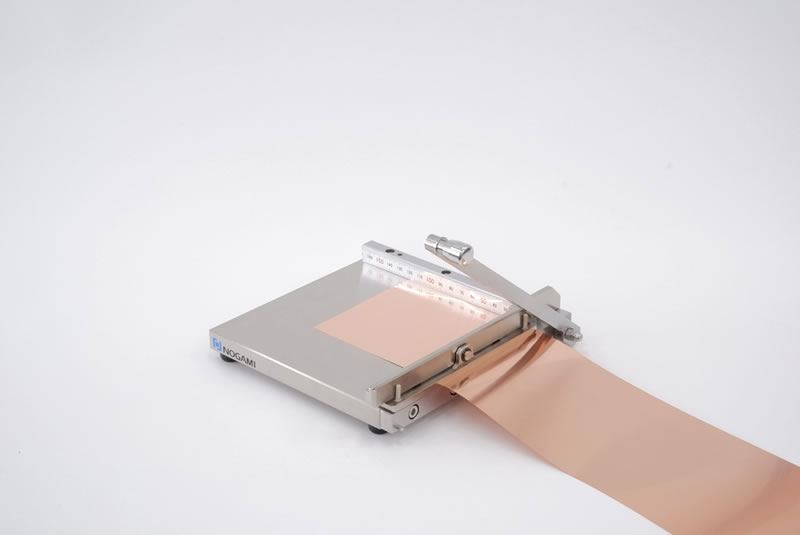

Cut surface finishing jig for cross-sectional observation samples

Simple cantilever-type electrode cutting machine

(Cutting width:50 mm/120 mm)

Precision gate-type electrode cutting machine

(Cutting width:150 mm/250 mm)

Clean Press

– Cassette type punching jig

(Max. 50 x 70 mm)

Handheld Electrode Punch for quality control F100 mm

Precision test piece cutting jig

(dumbbell shape / strip shape)

Variable precision coating applicator

Historical Highlights

| 1970 | Nogami Seiken established by Shinryo Nogami |

| 1986 | Changed the company name to Nogamigiken Co., Ltd. |

| 1987 | Built Number 1 factory and started operation in Ibaraki Pref. |

| 1989 | Built Number 2 factory in Ibaraki Pref. |

| 1990 | Started the stamping products and services |

| 1997 | Built Number 3 factory in Ibaraki Pref. |

| 1999 | Obtained ISO 9002 certification for Ibaraki factories. |

| 2001 | Extended Number 2 factory |

| 2004 | Obtained ISO 9001: 2000 certification for Ibaraki factories |

| 2009 | Selected by METI as one of “300 of Japan’s Vibrant Monodzukuri (an art of making goods) small and medium enterprises” (SMEs) |

| 2009 | Adopted by METI as a company to receive a subsidy for product development of Monodzukuri SMEs |

| 2010 | Adopted by JETRO as a company to receive the support service to export hopeful products as exportation |

| 2010 | Adopted by METI as a company to receive a subsidy for SME’s R & D to develop new technology. [Developed an innovative stamping die to blank out glass epoxy PCB (FR4)] |

| 2011 | Registered on the IGES as certificate of Eco Action 21 |

| 2011 | Machine Parts Award of Super Manufacturing Parts Award by Nikkan Kogyo Shimbun |

| 2013 | Encouragement Award of 25th Small and Medium-sized Enterprises Excellent Technologies & New Products Award |

| 2015 | Economic and Industrial Manufacturing Industries Bureau Director’s Award of 31st Formed and Fabricated Materials Industry Technology Award |

| 2016 | Received an award in the Environmental Management Division at the “Eco-Friendly Company” awards hosted by Ibaraki Prefecture. |

| 2017 | Started the Solution Services business. |

| 2017 | Certifi ed as Companies Driving Regional Growth by the Ministry of Economy, Trade and Industry. |

Company Profile

| Corporate name | NOGAMIGIKEN CO., LTD. |

| President and CEO | Ryota Nogami |

| capital | Ten million yen |

| Address | Headquarters: 5-9-3 Megurohoncho, Meguro Ward, Tokyo, JAPAN Ibaraki Factory: 1136-3 Izumi, Hitachiomiya City, Ibaraki-Pref., JAPAN TEL(81)-295-53-2188 FAX(81)-295-53-1228 |

| Employees | 60 |

| Products and Services | Precision machining parts; Ultra-precision jig; Precision stamping parts andDesign and manufacture of precision progressive stamping die |

Access (Ibaraki Factory)

By Train:Get off at Hitachi-Omiya Station on the JR Suigun Line, then take a taxi for about 10 minutes.

By Car:About 20 minutes from Naka Interchange on the JOBAN EXPWY.